- Main Parameters

- FAQ

Wood Lag Screws:

DIN 571

Material: Steel

Size: M4-20

Length:16-170mm

Surface: Hot dip galvanized/ Zinc plated

Head type: Hexagon head

Thread type: Wood screw thread

Shape of tip: Tip

RoHS-compliant: Yes

Details:

For solid wood connections

Hexagon head for improved application of force when screwing in

The wood screw forms its nut thread instead of cutting it

Depending on the diameter, pre-drilling must be carried out

Usage:

Application area

For wooden construction, excluding areas requiring approval. Areas of application are, for example roof construction, carport construction, interior construction, electrical work, cable ducts in connection with anchors

Instructions

Depending on the screw diameter, pre-drilling must be carried out

In the case of steel connections, the metal must be pre-drilled corresponding to the screw diameter (max. + 1 mm) and the wood according to the screw core diameter

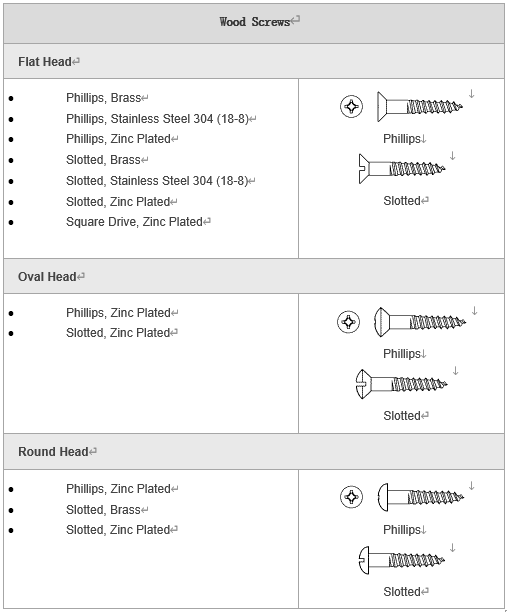

Wood Screws

Wood screws are used to fasten wood to wood or attach objects to wood and offer a pleasing, finished appearance. They pull wood pieces together as they are tightened, which can make clamping unnecessary, and can be removed more easily than nails so entire assemblies can be dismantled or fixtures dismounted with relative speed. Although lateral resistance (shear) may only be slightly better than similarly sized driven nails, wood screws offer greater withdrawal resistance. For example, a 20d (20 penny) common nail (0.192" diameter) has a withdrawal load design value of 42 lbs./in. of penetration in the side grain of wood having a specific gravity of 0.48 (such as Douglas Fir, South). In comparison, a #10 wood screw (0.190" diameter) has a withdrawal design value of 124 lbs./in. of thread penetration under the same conditions. Table 1 lists common wood screw types and styles.

THREADS and POINT

Wood screws have sharp crested, coarse, widely spaced threads (see Table 2 for the number of threads per inch for each screw size). Being a thread-forming-type screw, they create their own mating threads during installation—no nut or tapped hole is needed. A gimlet point allows wood screws to start threading into wood easily: "A gimlet point is a threaded cone point usually having a point angle of 45 to 50 degrees." Threading is standard right-hand, so turn the screw clockwise to install.

Screws with cut threads are tapered and about two-thirds of their length is threaded—the remaining one-third is an unthreaded section of the shank adjacent to the head, called the body. Wood screws with rolled threads are not tapered and "at least four times the basic screw diameter or two-thirds of the nominal screw length, whichever is greater" is threaded. For screws with cut threads, the thread crest diameter is no larger than the body diameter, and the body diameter is larger than same-sized screws with rolled threads. For screws with rolled threads, the thread crest diameter is larger than the body diameter, and the body diameter is smaller than same-sized screws with cut threads. The unthreaded body is said to help prevent two wood pieces from separating as they are screwed together.

SIZES

Wood screws range in diameter from #0 to #24; the larger the number, the larger the size and, unlike wire gauge, #0 is the smallest screw size. Sizes from #2 to #14 are commonly available. The number size does not relate to any measurement—use Table 2 to determine basic diameter in inches.

LENGTHS

Lengths range from 1/4" to 6"; 5" or so is the longest typically found and larger screw sizes are offered in the longer lengths. Sizes less than 1" are in 1/8" increments; lengths from 1" to 3" are in 1/4" steps; and screws longer than 3" increase in length by 1/2". Wood screws are measured like other screws: "The length of a headed fastener is the distance from the intersection of the largest diameter of the head with the bearing surface to the extreme point…" (the bearing surface is the part of the head that contacts the mating surface). For flat heads, length is measured from the top of the head to the tip of the thread; measure oval heads from the largest diameter point—where the dome top meets the conical bearing surface—to the threaded tip; and round heads are measured from under the head to the screw's tip.

DRIVE STYLES

Drive styles include slotted, cross recessed (Phillips) and square recessed. Due to the tendency of cam out (the driver bit slips or twists out of the drive recess), slotted screws are often not used with power drivers (the chance of damaging the screw head, driver bit or marring the wood surface is too great). Consequently, use Phillips and square drive wood screws with power drivers but hand drive slotted screws (square drive is more resistant to cam out than Phillips). Driver bit sizes are listed in Table 3.

HEAD TYPES

Three head types are common: flat (countersunk), oval (countersunk) and round. The head angle (conical bearing surface) of flat and oval heads is 82°. Although ANSI Standard B18.6.1-1981 (R2003) provides specifications for pan heads, pan head wood screws are largely non-existent. Flat heads are probably the most popular because their head, when countersunk, is flush with the mating surface. In addition, flat head screws can be easily concealed using a color-coordinated-plastic screw cover; filler or a wood plug can be used if the head is sufficiently countersunk (see below). Oval and round heads are considered decorative and often left exposed. Refer to Table 2 for a summary of average head diameters.

Table 2. Wood Screw Dimensions, Sizes, Head Diameters & Threads per Inch. Wood screw dimensions, nominal sizes and average head diameters, in decimal and fractional inches, and threads per inch. (Note: Fractional size is decimal size rounded to nearest 64th.) | |||||||

Wood Screw Dimensions, Sizes, Head Diameters & Threads per Inch | |||||||

Nominal | Threads | Basic Diameter | Average Head Diameter | ||||

Flat & Oval | Round | ||||||

Decimal | Fraction | Decimal | Fraction | Decimal | Fraction | ||

0 | 32 | 0.060 | 1/16 | 0.109 | 7/64 | 0.106 | 7/64 |

1 | 28 | 0.073 | 5/64 | 0.135 | 9/64 | 0.130 | 1/8 |

2 | 26 | 0.086 | 3/32 | 0.160 | 5/32 | 0.154 | 5/32 |

3 | 24 | 0.099 | 3/32 | 0.185 | 3/16 | 0.178 | 11/64 |

4 | 22 | 0.112 | 7/64 | 0.210 | 13/64 | 0.202 | 13/64 |

5 | 20 | 0.125 | 1/8 | 0.236 | 15/64 | 0.227 | 7/32 |

6 | 18 | 0.138 | 9/64 | 0.262 | 17/64 | 0.250 | 1/4 |

7 | 16 | 0.151 | 5/32 | 0.287 | 9/32 | 0.275 | 9/32 |

8 | 15 | 0.164 | 5/32 | 0.312 | 5/16 | 0.298 | 19/64 |

9 | 14 | 0.177 | 11/64 | 0.337 | 11/32 | 0.323 | 21/64 |

10 | 13 | 0.190 | 3/16 | 0.363 | 23/64 | 0.347 | 11/32 |

12 | 11 | 0.216 | 7/32 | 0.414 | 13/32 | 0.395 | 25/64 |

14 | 10 | 0.242 | 15/64 | 0.480 | 31/64 | 0.443 | 7/16 |

16 | 9 | 0.268 | 17/64 | 0.515 | 33/64 | 0.491 | 31/64 |

18 | 8 | 0.294 | 19/64 | 0.602 | 19/32 | 0.539 | 17/32 |

20 | 8 | 0.320 | 5/16 | 0.616 | 39/64 | 0.587 | 19/32 |

24 | 7 | 0.372 | 3/8 | 0.724 | 23/32 | 0.683 | 11/16 |

MATERIALS and FINISHES

Common materials are unhardened steel (usually zinc plated), stainless steel, brass and silicon bronze. Zinc plating offers moderate corrosion resistance for steel. Brass provides better protection, while silicon bronze and stainless steel are known for their superior protection against corrosion. Stainless steel and silicon bronze are usually recommended if the screws will be used with pressure preservative treated wood such as "ACQ" (Alkaline Copper Quaternary)—check local building codes and contact your lumber supplier for recommendations. (Hot dip galvanized screws may also be used with treated wood but galvanizing is not a common finish for wood screws.) In marine environments, "stainless steels are subject to potentially severe pitting-corrosion attack when immersed in salt water, without free-oxygen," which makes silicon bronze a preferred material because stainless steel needs oxygen to create its self-healing, corrosion-resisting chromium oxide film. In terms of physical strength, steel, stainless steel and silicon bronze are all stronger than brass (brass is characterized as a soft material). Steel is magnetic, stainless steel may be slightly magnetic, and brass and silicon bronze, being nonferrous (not made of iron), are nonmagnetic. Stainless steel, brass and silicon bronze wood screws are more expensive than steel.

DESIGNATION

Wood screws are typically described as follows:

· Nominal Size (a number from #0 to #24; #0 is smallest)

· Screw Length (in inches; see above for instructions on how to measure)

· Drive Style (slotted, Phillips or square)

· Head Type (flat or oval countersunk, or round)

· Fastener Name (wood screw)

· Material (steel, stainless steel, brass and silicon bronze)

· Protective Finish (zinc plated if steel)

ONLINE

ONLINE Inquiry

Inquiry